HDPE with Bauer Fittings Vs. Heat Fusion

In fluid transport systems across various industries, the choice of piping material and joining method is critical in ensuring efficiency, durability, and cost-effectiveness. High-Density Polyethylene (HDPE) pipes, known for their versatility and resilience, coupled with Bauer fittings, offer distinct advantages over traditional heat fusion methods. This article delves into the benefits of utilizing HDPE pipes with Bauer fittings compared to heat fusion joining techniques.

1. Enhanced Flexibility and Versatility

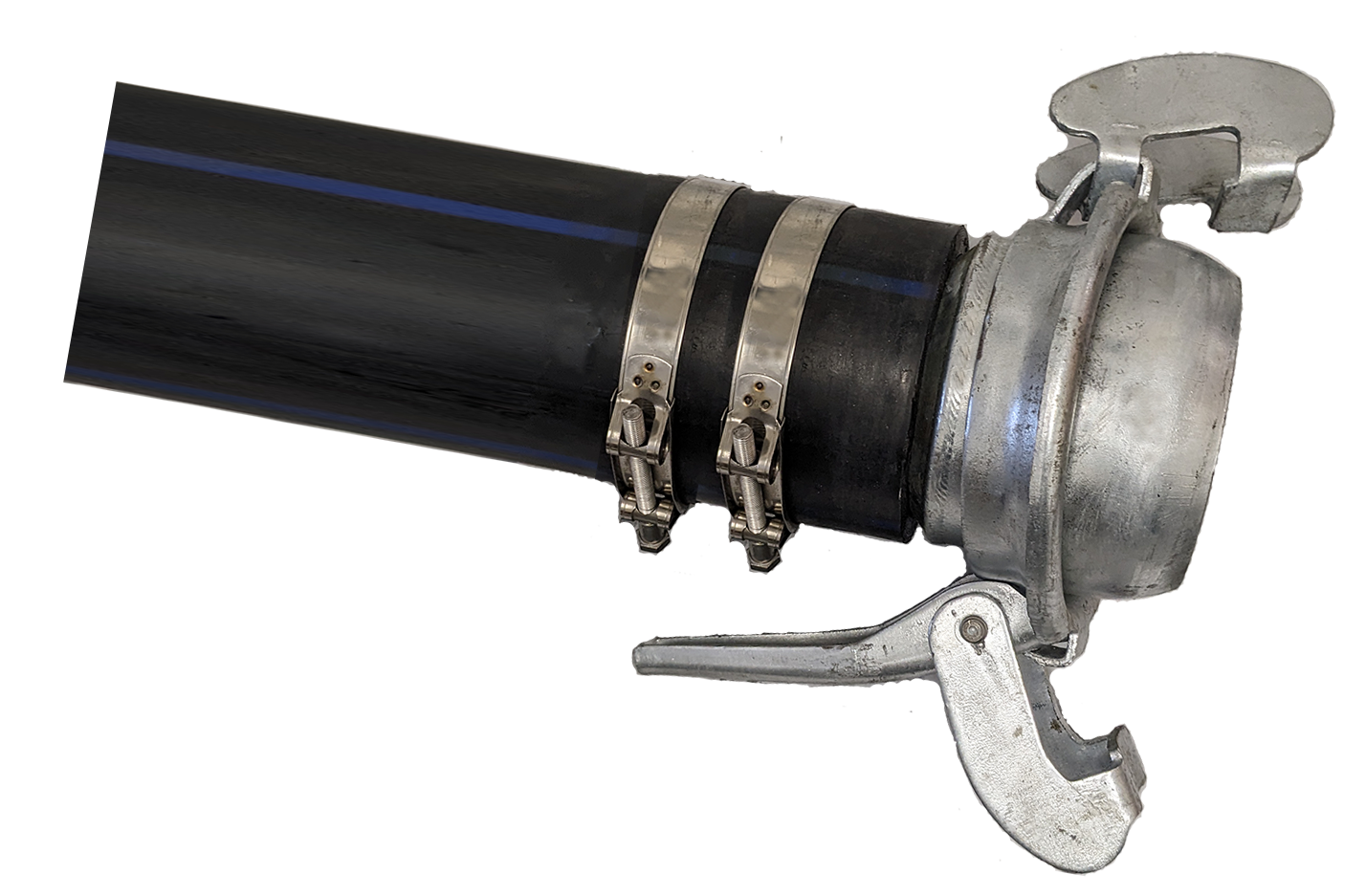

HDPE pipes possess inherent flexibility, allowing them to adapt to various terrain conditions and installation requirements. The system offers unparalleled versatility when combined with Bauer fittings, which provide a quick and secure connection mechanism. Unlike heat fusion, which requires precise alignment and controlled temperatures (which are not always available in outdoor conditions), Bauer fittings enable easy assembly even in challenging environments, reducing installation time and labor costs.

2. Non-Destructive Joining Process

One of the critical drawbacks of heat fusion joining is its irreversible nature, often resulting in potential damage to the pipe’s molecular structure. In contrast, Bauer fittings offer a non-destructive joining process that preserves the integrity of the HDPE pipes. With Bauer fittings, pipes can be assembled and disassembled multiple times without compromising performance, providing greater flexibility in system modifications or repairs.

3. Time and Cost Savings

The efficiency of HDPE pipes with Bauer fittings significantly reduces installation time and labor costs compared to heat fusion methods. Traditional heat fusion requires specialized equipment, skilled operators, and meticulous preparation, contributing to higher project expenses. In contrast, Bauer fittings facilitate rapid assembly with minimal tools, simplifying installation and accelerating project timelines. Additionally, the reusability of Bauer fittings minimizes material waste, further optimizing overall project costs. This reusability has ensured that renting HDPE pipe from Anaconda is such a game-changer for short term projects.

4. Enhanced Resistance to Environmental Factors

HDPE pipes exhibit exceptional resistance to corrosion, abrasion, and chemical degradation, making them ideal for various applications, including water distribution, mining, agriculture, and wastewater management. When paired with quick disconnect fittings such as Bauer fittings, the system maintains its integrity even in harsh operating environments. Unlike heat fusion joints, which may be susceptible to environmental stress cracking or thermal degradation, HDPE pipes with Bauer fittings offer long-term reliability and performance.

5. Seamless Integration with Existing Infrastructure

The compatibility of Bauer fittings with standard pipe diameters and configurations enables seamless integration with existing infrastructure. Whether upgrading or expanding a fluid transport system, HDPE pipes with Bauer fittings provide a versatile solution that can adapt to diverse project requirements. This compatibility facilitates easier retrofitting of older pipelines or integration with other piping materials, offering greater system design and optimization flexibility.

In most cases, HDPE pipes with Bauer fittings present numerous advantages over traditional heat fusion joining methods. This innovative solution offers unparalleled efficiency and reliability in fluid transport applications across various industries, from enhanced flexibility and non-destructive assembly to time and cost savings. By leveraging the benefits of HDPE pipes with Bauer fittings, organizations can optimize their operations, minimize downtime, and achieve sustainable long-term performance.

0 Comments