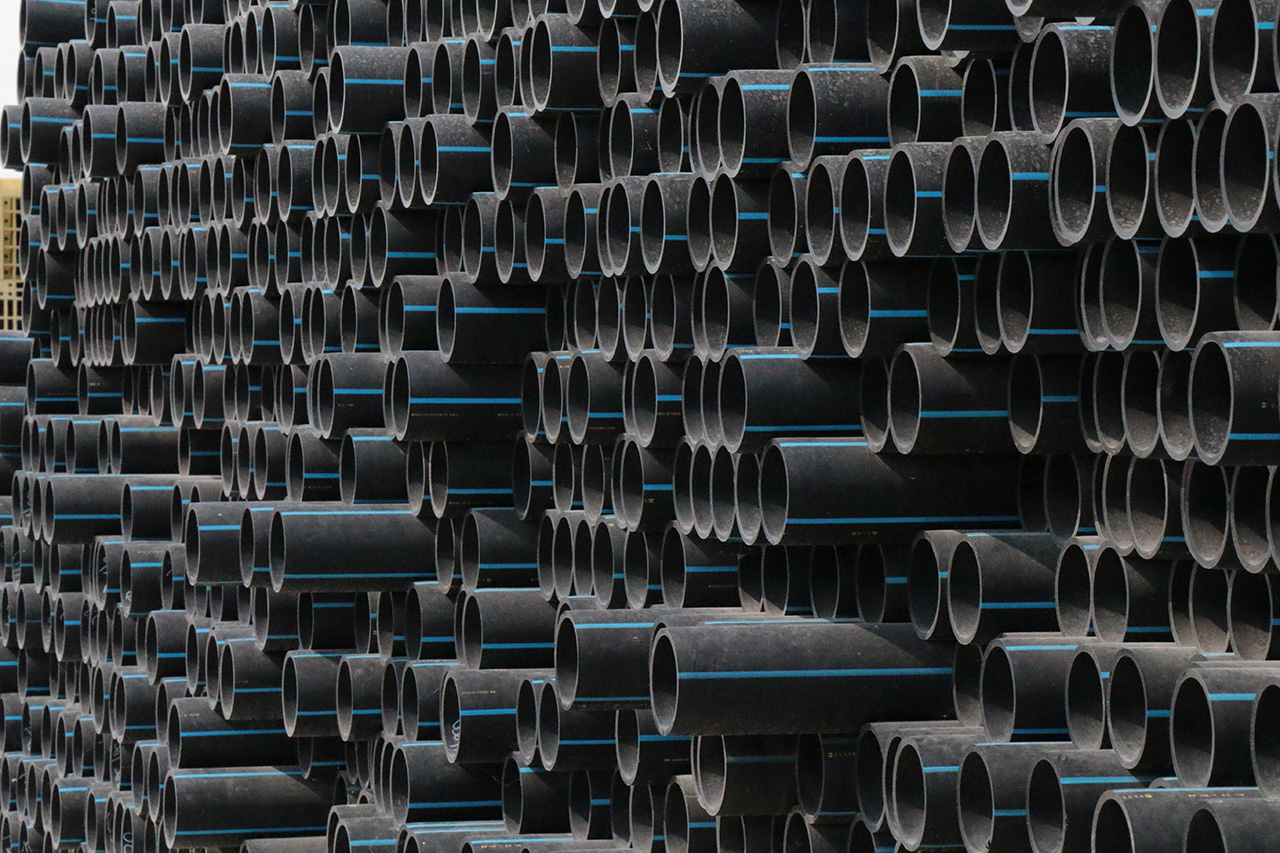

Introduction to High Density Polyethylene (HDPE) Pipes

High-density polyethylene (HDPE) pipes are a type of thermoplastic pipe made from high-density polyethylene resin. Renowned for their exceptional strength and durability, HDPE pipe is a top choice for various applications, including potable water, sewage, and industrial processes. One of the standout features of HDPE pipes is their remarkable resistance to corrosion, which ensures longevity and reliability even in the harshest environments. Additionally, HDPE pipes are highly resistant to environmental factors such as temperature fluctuations, rain, and wind, making them an excellent option for outdoor installations when compared with ductile iron. This resilience to environmental stressors ensures that HDPE pipes maintain their integrity and performance over time, providing a dependable solution for industrial project managers.

Benefits of HDPE Pipes

HDPE pipes offer numerous benefits over other materials, making them a preferred choice for industrial applications:

- Corrosion Resistance: HDPE pipes are highly resistant to corrosion, making them ideal for applications where corrosion is a concern. This ensures a longer lifespan and reduced maintenance costs.

- Impact Resistance: With their high toughness, HDPE pipes can withstand significant impacts without fracturing, making them reliable in environments where mechanical damage is a risk.

- Light Weight: HDPE pipes are significantly lighter than other materials, which simplifies handling and transportation, reducing labor costs and installation time.

- Chemical Resistant: HDPE pipes are highly resistant to a wide range of chemicals, making them suitable for applications involving chemical exposure.

- Zero Leak Rate: The seamless construction of HDPE pipes ensures a zero leak rate, providing a reliable solution for applications where leak prevention is critical.

- Highly Resistant to Environmental Factors: HDPE pipes can withstand temperature changes, rain, and wind, ensuring consistent performance in various environmental conditions.

These benefits make HDPE pipes a versatile and cost-effective choice for industrial project managers looking to optimize their piping infrastructure.

Applications of HDPE Pipes

HDPE pipes are widely used in a variety of applications due to their exceptional properties:

- Potable Water: HDPE pipes are an ideal choice for potable water applications due to their corrosion resistance and zero leak rate, ensuring safe and clean water delivery.

- Sewage: The impact resistance and corrosion resistance of HDPE pipes make them perfect for sewage systems, where durability and reliability are paramount.

- Industrial Processes: HDPE pipes are well-suited for industrial processes that involve high pressure and chemical exposure, thanks to their chemical resistance and strength.

- Telecommunications Cables: HDPE pipes provide excellent protection for telecommunications cables, offering corrosion resistance and impact resistance to safeguard the cables.

- Earthquake Prone Areas: The flexibility and impact resistance of HDPE pipes make them an ideal choice for regions prone to earthquakes, as they can withstand ground movements without damage.

These diverse applications highlight the versatility and reliability of HDPE pipes, making them a valuable asset in various industrial settings.

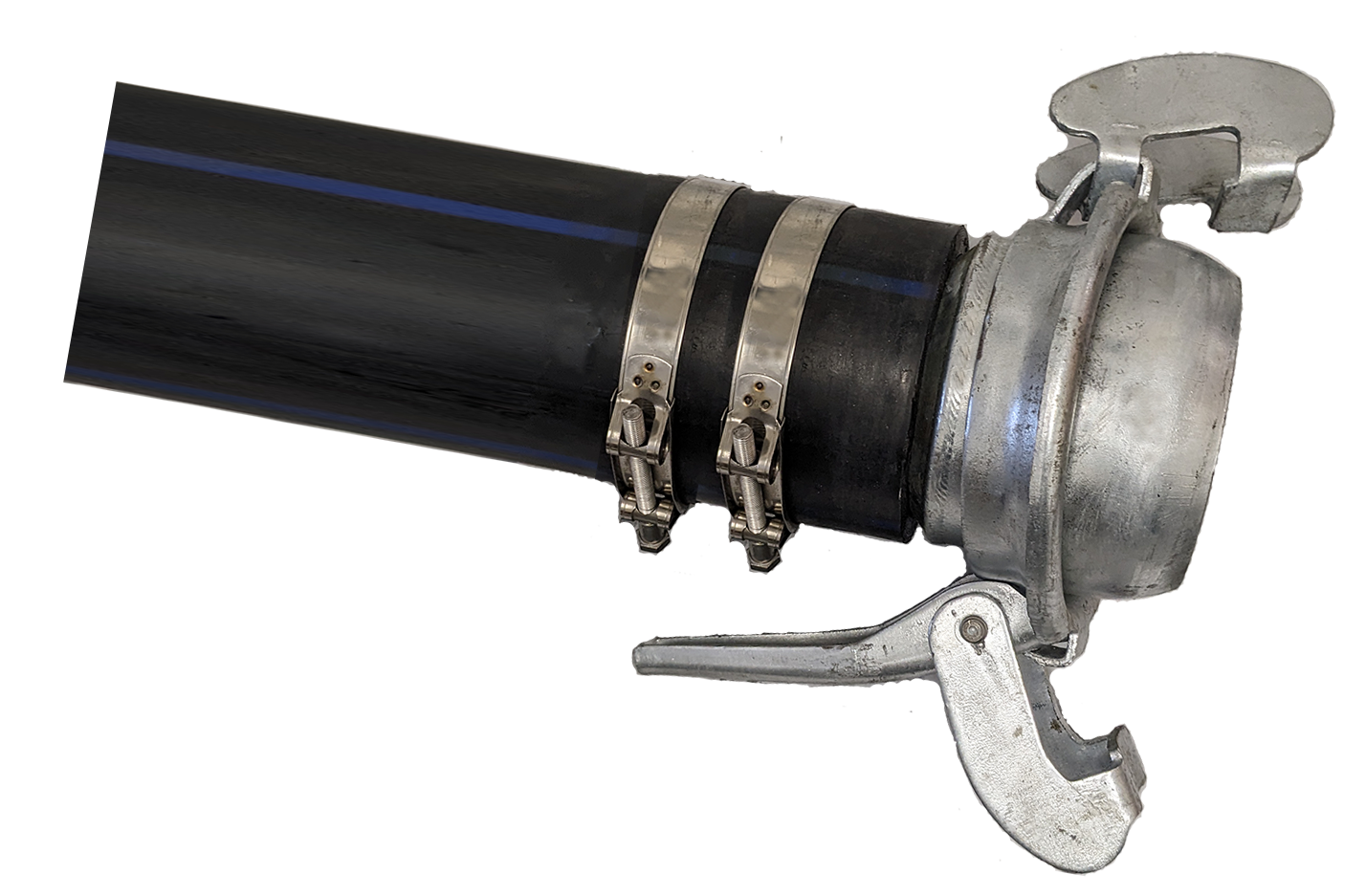

High Density Polyethylene with Bauer Fittings Vs. Heat Fusion

If you’re involved in industrial project management, selecting the right piping material is crucial for the success and efficiency of your projects. While various options are available, High-Density Polyethylene (HDPE) pipes offer distinct advantages over Polyvinyl Chloride (PVC) pipes in industrial applications. This article explains why industrial project managers should consider HDPE pipes as their preferred choice.

1. Durability and Longevity

One of the key advantages of HDPE pipes over PVC pipes is their superior durability and longevity. HDPE pipes are highly resistant to corrosion, abrasion, and chemical degradation, making them ideal for industrial environments with harsh conditions. Unlike PVC pipes, which may become brittle over time and susceptible to cracking, HDPE pipes retain their structural integrity even in challenging operating conditions. As an industrial project manager, investing in HDPE pipes ensures long-term reliability and minimizes the risk of costly repairs or replacements.

2. Flexibility and Adaptability

HDPE pipes offer greater flexibility and adaptability than PVC pipes, allowing for easier installation and alignment in industrial settings. HDPE pipes can be bent and maneuvered to navigate obstacles or follow existing infrastructure layouts without additional fittings or joints. This flexibility reduces the complexity of installation, saves time, and minimizes the risk of leaks or failures at connection points. HDPE pipes are also available in longer coil lengths, reducing the required joints and enhancing system integrity.

3. Resistance to Impact and Fracture

In industrial environments where mechanical impacts are expected, HDPE pipes outperform PVC pipes in terms of resistance to fracture and damage. HDPE pipes have a high toughness and can absorb impacts without fracturing or breaking, ensuring continuous operation even in high-traffic areas or areas prone to ground movement. This resilience minimizes the risk of downtime and associated costs, providing industrial project managers with peace of mind knowing that their piping infrastructure can withstand the rigors of daily operations.

4. Cost-Effectiveness

While the initial cost of HDPE pipes may be slightly higher than PVC pipes, the long-term cost-effectiveness of HDPE cannot be overstated. HDPE pipes require minimal maintenance and have a significantly longer service life than PVC pipes, resulting in lower life cycle costs. Additionally, the flexibility and lightweight nature of HDPE pipes reduce installation time and labor costs, further contributing to overall cost savings. As an industrial project manager, opting for HDPE pipes allows you to maximize your budget and allocate resources more efficiently over the lifespan of your projects.

5. Environmental Sustainability

In today’s environmentally conscious landscape, sustainability is a crucial consideration for industrial project managers. HDPE pipes are inherently more eco-friendly than PVC pipes due to their recyclability and lower environmental impact. HDPE is a thermoplastic material that can be recycled and reused multiple times without compromising its properties, reducing the need for virgin materials and minimizing waste. Furthermore, HDPE pipes have a lower carbon footprint compared to PVC pipes throughout their lifecycle, making them a more sustainable choice for industrial applications.

6. Resistance to Chemicals and Corrosive Substances

In industrial settings where exposure to chemicals and corrosive substances is everyday, HDPE pipes offer superior resistance to PVC pipes. HDPE is chemically inert and does not react with most acids, alkalis, or other corrosive agents, ensuring the integrity of the piping system over time. This resistance minimizes the risk of leaks, contamination, and environmental hazards, providing added safety and reliability in industrial operations.

While PVC pipes may offer certain advantages, such as lower initial cost, HDPE pipes are the preferred choice due to their superior durability, flexibility, cost-effectiveness, environmental sustainability, and resistance to impact and chemicals. By opting for HDPE pipes, industrial project managers can ensure the long-term reliability and performance of their piping infrastructure, ultimately driving the success of their projects and enhancing their organization’s bottom line.

Conclusion

In conclusion, HDPE pipes are a reliable and durable choice for a wide range of applications. Their exceptional strength, corrosion resistance, and impact resistance make them an ideal choice for applications where reliability and durability are critical. Additionally, their light weight, chemical resistance, and zero leak rate make them an ideal choice for applications where these factors are important. Whether you’re looking for a reliable pipe for potable water, sewage, or industrial processes, HDPE pipes are an excellent choice. By opting for HDPE pipes, industrial project managers can ensure the long-term reliability and performance of their piping infrastructure, ultimately driving the success of their projects and enhancing their organization’s bottom line.

0 Comments