- Understanding Slurry Piping

- The Importance of Piping System for Slurry in Mining

- 1. Cost-Effective Solution

- 2. High-Speed Material Transport

- 3. Enhanced Worker Safety

- 4. Environmentally Friendly

- 5. Versatility in Challenging Terrains

- Applications in Mining Operations

- 1. Mineral Extraction

- 2. Mineral Processing

- 3. Waste Management

- 4. Product Transportation

- Types of Slurry Piping

- Selecting the Right Piping for your slurry

- Maintaining Slurry Piping Systems

- Innovations in Piping systems:

- Challenges in Slurry pipelines

- Conclusion

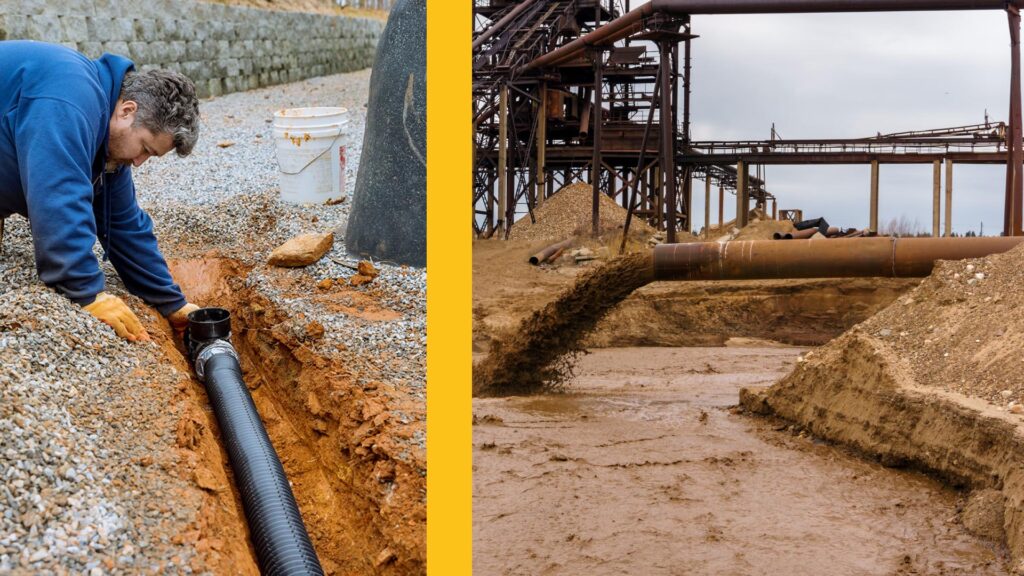

Mining and mineral processing industries rely heavily on efficient material transport systems. One of the most crucial methods in this field is slurry piping. This technique is essential for moving thick mixtures of water and finely ground materials, such as rocks or minerals. Let’s explore why slurry piping is so important and how it enhances mining operations.

Understanding Slurry Piping

Using a Piping System for Slurry is a specialized method for transporting dense, muddy mixtures through pipelines. These mixtures, known as slurries, consist of water and tiny solid particles like rock or mineral fragments. In the mining industry, it plays a vital role in moving these materials efficiently from one location to another.

The Importance of Piping System for Slurry in Mining

Slurry piping offers numerous advantages in mining and mineral processing. Here’s why it’s so valuable:

1. Cost-Effective Solution

Implementing slurry pipe systems can lead to significant cost savings. Compared to traditional methods like trucks or trains, slurry handling pipes require less energy to operate. They also have a longer lifespan, reducing the need for frequent repairs or replacements. This allows mining companies to allocate their resources more effectively.

2. High-Speed Material Transport

Slurry pipe systems can move large volumes of material rapidly. They operate continuously, day and night, enabling mines to increase their productivity and output. This efficient transport method can significantly boost a mine’s production capacity.

3. Enhanced Worker Safety

Using piping reduces the risk of accidents compared to other transport methods. It minimizes the need for workers to be present in hazardous areas, creating a safer work environment overall.

4. Environmentally Friendly

Slurry piping is more eco-friendly than traditional transport methods. It produces less pollution and noise, making it less disruptive to the surrounding ecosystem. This helps mining operations maintain better relationships with local communities and comply with environmental regulations.

5. Versatility in Challenging Terrains

Slurry transfer piping can be installed in difficult-to-reach locations. It can traverse hills, forests, and even underground passages, making it possible to access mineral deposits in remote or challenging areas.

Applications in Mining Operations

In Operations like mining and mineral processing, it is useful in various stages:

1. Mineral Extraction

When miners extract ore-bearing rocks, they often mix them with water to create a slurry. This slurry is then transported via slurry piping systems to processing facilities. This method is faster and more efficient than using trucks.

2. Mineral Processing

During the cleaning and sorting stages, slurry handling pipes move the minerals through various processing equipment. This streamlines the entire operation, making it more efficient and reducing the need for multiple loading and unloading steps.

3. Waste Management

Mining generates significant amounts of waste material. It helps transport this waste to designated storage areas, keeping the mining site clean and safe.

4. Product Transportation

Once minerals are processed, slurry pipe systems can transport the final product to shipping facilities. This ensures a quick and secure method of getting the product ready for market.

Types of Slurry Piping

Different types of systems of pipelines are used based on specific needs:

- Metal Pipes: Ideal for handling abrasive materials.

- Rubber-Lined Pipes: Suitable for softer materials and offer wear protection.

- Plastic Pipes: Lightweight and corrosion-resistant, good for less abrasive slurries.

- Concrete Pipes: Used in large-scale operations for heavy slurries.

- Ceramic-Lined Pipes: Highly wear-resistant for extremely abrasive slurries.

Selecting the Right Piping for your slurry

Choosing the appropriate piping is crucial. Consider these factors:

- Slurry Composition: Different materials require different pipe types.

- Volume: Ensure the pipes can handle the necessary slurry volume.

- Distance: Longer distances may need stronger pipes.

- Environmental Conditions: Consider temperature extremes and other environmental factors.

- Cost: Balance initial costs with long-term durability.

- Pressure Requirements: Choose pipes that can withstand the system’s pressure.

- Maintenance Needs: Consider the ease of maintenance for different pipe types.

Maintaining Slurry Piping Systems

Proper maintenance is essential for effective slurry piping:

- Regular Inspections: Frequently check pipes for signs of wear or damage.

- Cleaning: Regularly clean pipes to prevent blockages.

- Prompt Repairs: Address any issues immediately to prevent larger problems.

- Optimal Flow Rate: Maintain the correct slurry flow speed to minimize wear.

- Staff Training: Ensure all workers know how to operate and maintain the system safely.

- Record Keeping: Maintain detailed maintenance logs for better system management.

- Proper Tools: Use appropriate equipment for maintenance and repairs.

Innovations in Piping systems:

The field of Slurry pipelines continues to evolve:

- Smart Pipes: These are equipped with sensors to detect issues early.

- Advanced Materials: New alloys and composites offer improved durability.

- Improved Designs: New pipe shapes reduce turbulence and wear.

- Eco-Friendly Options: Pipes made from recycled materials or designed for energy efficiency.

- Self-Healing Pipes: Experimental pipes that can repair minor damage automatically.

- Advanced Coatings: New internal coatings reduce friction and extend pipe life.

Challenges in Slurry pipelines

Despite its benefits, slurry piping faces some challenges:

- Wear and Tear: Abrasive slurries can cause significant pipe erosion over time.

- Blockages: Pipes can become clogged if the slurry is too thick or contains large particles.

- Leaks: Pipe breakages can lead to slurry leaks, posing environmental risks.

- Freezing: In cold climates, slurry may freeze inside pipes, causing damage.

- Initial Costs: Installing a slurry piping system requires significant upfront investment.

- Changing Slurry Properties: As mines progress, the slurry composition may change, requiring system adjustments.

- Maintenance Difficulties: Some parts of the system may need help to access for maintenance.

Conclusion

Slurry piping is a cornerstone of efficient mining and mineral processing operations. It offers a safe, cost-effective, and fast method of material transport. By utilizing slurry handling pipes, mines can enhance their productivity while minimizing environmental impact.

As technology advances, we can expect further improvements in slurry pipe systems. These advancements will continue to make mining operations more efficient and sustainable. The future of mining relies heavily on effective slurry piping to meet the growing global demand for minerals responsibly.

Understanding and implementing effective slurry piping is crucial for modern mining operations. It not only improves efficiency but also contributes to safer and more environmentally friendly mining practices. As the industry evolves, slurry transfer piping will undoubtedly play an increasingly important role in shaping the future of mining and mineral processing.

0 Comments