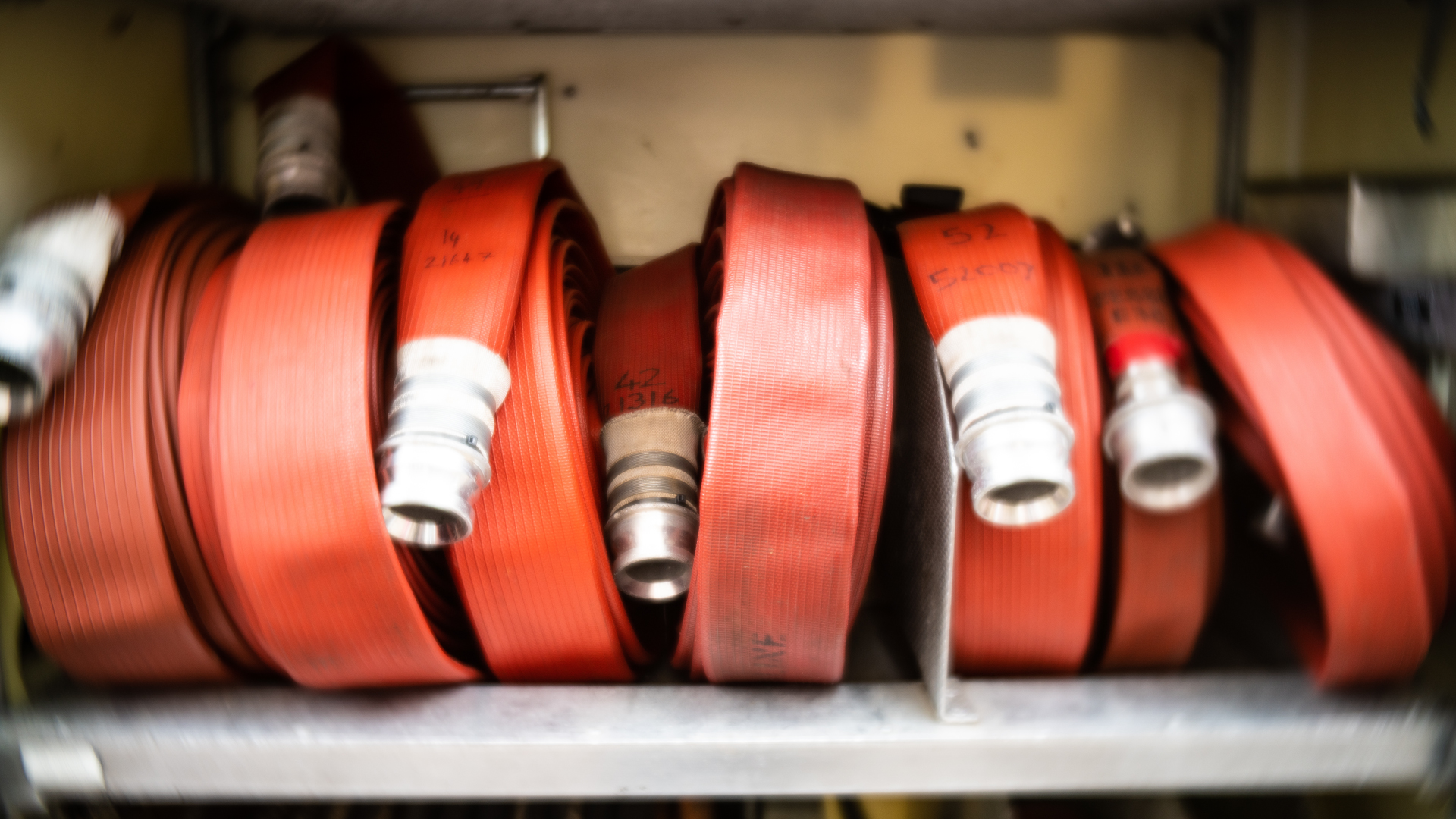

Firefighting hose is the lifeline of fire suppression efforts, transporting large volumes of water and sometimes foam to contain and extinguish fires. As fire scenarios become more complex, so does the need for more advanced hose for firefighting equipment. One critical component of this equipment is the firefighting hose. Recent innovations have transformed firefighter hose, making them lighter, stronger, and more efficient. These advancements aim to improve both firefighter safety and performance on the job.

Evolution of Firefighting Hose

The fire suppression hose has undergone significant changes since its early days. Historically, hoses were made from rubber or leather, which were heavy, stiff, and prone to damage over time. With advances in material science, modern hoses now use synthetic materials like polyurethane and nitrile, offering improved performance and durability.

Key milestones in fire suppression hose technology include the introduction of synthetic woven jackets, making hoses lighter and more resistant to abrasion. In recent years, new coatings and chemical treatments have been applied to enhance the hoses’ resistance to chemicals, UV radiation, and fire. The evolution of these materials has resulted in hoses that can endure higher temperatures, greater pressure, and more rugged environments.

The driving forces behind these innovations are centered on enhancing durability, increasing flexibility, and improving heat resistance—three critical elements for a firefighting hose to be effective in dangerous, high-stakes environments.

Material Advancements in Firefighting Hose

One of the most significant advancements in a firefighting hose is the use of material. Lightweight and durable materials, such as polyurethane and synthetic polymers, have replaced heavier rubber hoses. These materials provide several advantages, including improved strength, flexibility, and abrasion resistance.

Firefighters benefit from these advancements with increased maneuverability during operations. In an emergency, seconds count, and the ability to move quickly while carrying and deploying firefighter hose can save lives. Lighter hoses also reduce firefighter fatigue, enabling them to fight fires more effectively for longer periods.

These modern materials also enhance the hose’s resistance to environmental factors, such as chemicals, water, and heat. This improvement in durability ensures that hoses last longer and can handle the toughest conditions, reducing the need for frequent replacements and saving costs.

Heat and Pressure Resistance

Firefighting involves fighting extreme heat, so hoses must be able to withstand high temperatures without melting or becoming damaged. Recent innovations have led to new fire safety hose coatings and materials that are more resistant to heat. These include multi-layer constructions designed to insulate against extreme heat exposure, ensuring that hoses do not fail during intense hose for firefighting scenarios.

Another critical aspect is pressure resistance. A firefighting hose is now being built to handle higher pressure levels. This allows water to be pumped over longer distances, making it easier to fight fires in large buildings, high-rise structures, or remote areas. Enhanced pressure rating capabilities also mean that hoses are less likely to burst or fail under extreme conditions, providing firefighters with reliable equipment when they need it most.

Smart Hose Technologies

One of the most exciting developments in fire suppression hose innovation is the introduction of smart technologies. Sensors embedded in hoses can now monitor critical factors like pressure, temperature, and water flow. These real-time data readings are transmitted to incident commanders, providing them with valuable insights for better decision-making during fire suppression operations.

Smart hoses also feature predictive maintenance technologies, alerting firefighters or maintenance teams to potential problems before they result in fire safety hose failures. This allows for proactive maintenance and reduces the risk of equipment failure in the middle of an operation, ensuring firefighter safety.

Improved Coupling and Connections

Another area of innovation is hose couplings and connections. New designs are focused on creating faster, more secure connections that can be made quickly under pressure. Improved anti-kink technologies also ensure that hose for firefighting can be deployed efficiently without the risk of water flow being blocked due to sharp bends or twists.

Flexible joints have also been introduced, allowing hoses to maintain full flow even in awkward or tight spaces. These advancements improve not only the hoses’ performance but also their compatibility with modern firefighting vehicles and equipment, making them more versatile in various hoses for firefighting situations.

Fire Hose Nozzle Innovations

The nozzle is another critical part of fire suppression hose technology, and recent innovations have made nozzles more efficient and versatile. Improved spray patterns and flow control allow firefighters to better manage water usage depending on the situation.

Variable flow rate nozzles enable firefighters to adjust the water output depending on the intensity of the fire. Additionally, modern nozzles often come with foam-dispensing capabilities, allowing for a dual approach to fire suppression. This integration of foam technology is crucial for fighting fires involving hazardous materials, where water alone may not be effective.

Environmental Considerations

In today’s environmentally conscious world, innovations in fire safety hose technology are not just about performance—they’re also about sustainability. Many modern hoses are now made using eco-friendly materials and manufacturing processes that reduce environmental impact.

Another critical innovation is the improvement in water usage efficiency. New technologies have reduced water waste during firefighting operations, helping to conserve water while still effectively extinguishing fires. Hoses are also becoming more recyclable, ensuring that worn-out equipment does not end up in landfills.

Training and Safety Enhancements

Firefighting is an inherently dangerous job, but innovation in firefighter hose is helping to reduce the risk. Modern hoses, thanks to their lighter weight and improved flexibility are designed to minimize firefighters’ fatigue. This makes it easier to handle them during extended operations, reducing the likelihood of injury.

Training for hoses for firefighting handling is also improving. Virtual reality (VR) simulations are now being used to train firefighters in hose deployment and handling. This technology allows firefighters to practice in a safe, controlled environment while experiencing real-world scenarios. Additionally, safety features such as color-coded hoses are being introduced, helping firefighters quickly identify hoses with different pressure levels or specific fire suppression uses.

The Future of Firefighting Hose Technology

Looking ahead, the future of fire suppression hose technology holds exciting potential. Ultra-lightweight hoses, improved chemical resistance, and enhanced durability are all areas where ongoing advancements are expected.

Artificial intelligence (AI) and machine learning are also set to play a role, potentially automating hose performance monitoring and offering insights into hose longevity and usage patterns. The continued integration of smart technologies will likely lead to even more data-driven firefighting strategies, ensuring that firefighters have the best possible equipment and information when they need it.

Conclusion

Firefighting hose technology has come a long way, with innovations that enhance durability, heat resistance, and smart capabilities. These advancements not only improve the effectiveness of fire suppression efforts but also ensure greater safety and efficiency for firefighters. As the challenges of firefighting evolve, so too will the technology, with continued innovation driving the future of fire suppression hose technology.

0 Comments