Construction

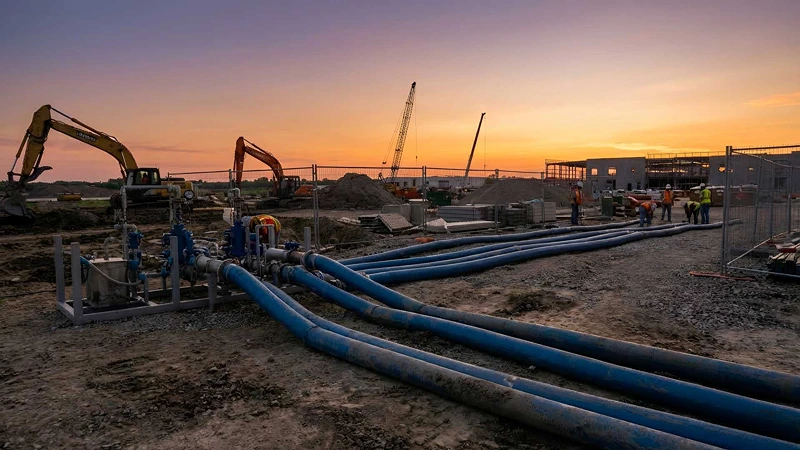

The construction industry demands pipe and hose systems that perform reliably under abrasive materials, heavy loads, fluctuating pressures, and constant handling. Anaconda supplies industrial hose and pipe systems for construction that support essential operations such as dewatering, material movement, concrete wash-out, slurry discharge, and temporary or permanent water lines. Our HDPE pipes for construction, slurry discharge hose, and lay flat hose for construction help minimize downtime, improve hydraulic efficiency, and withstand demanding site conditions.

Home

Industries

Construction

Engineered Pipe and Hose Systems for Construction Projects

Anaconda provides construction-grade hose and pipe systems designed for water transfer, abrasive slurry transport, dewatering, bypass operations, and utility installations. These solutions focus on durability, abrasion resistance, corrosion resistance, and simplified handling, all essential for civil, infrastructure, tunneling, mining, and industrial construction applications.

Our systems integrate smoothly with Bauer fittings construction, ANSI flange construction hoses, and standard construction pipe fittings, ensuring fast installation and reduced compatibility issues on fast-moving job sites.

HDPE Pipes for Construction Applications

Anaconda’s industrial HDPE pipeline offers reliable performance for both temporary and permanent construction water movement. These flexible HDPE construction pipes deliver long-service durability with low maintenance requirements, making them suitable for potable water routing, site drainage, trenching operations, dewatering mains, and general utility lines.

Key Advantages

- Corrosion-resistant construction pipe suitable for all weather and soil conditions

- Smooth internal bore that improves flow efficiency for high-volume pumping

- Lightweight for faster installation and reduced handling equipment

- Compatible with Bauer fittings, mechanical couplers, and fusion joints for flexible installation

- Suitable for stormwater transfer, bypass pumping, and long-distance water lines

- Strong impact resistance for uneven terrain and heavy machinery environments

HDPE pipe is commonly used to establish long-run site water distribution, dewatering trunks, bypass lines, and construction drainage systems that require predictable performance.

Slurry Discharge Hose for Construction Slurries & Abrasive Materials

Anaconda’s industrial slurry hose is built for construction tasks that involve sand, silt, aggregates, concrete fines, and abrasive solids, where hose failure can lead to costly downtime. This abrasion-resistant hose is engineered for high-pressure material transport and continuous duty cycles on construction and mining sites.

Key Advantages

- Slurry discharge hose with reinforced construction for high-solids flow

- Material transport hose engineered to handle abrasive slurry from excavation, drilling & dredging

- High-pressure capacity for pump discharge and booster systems

- Smooth bore options to maintain steady flow and reduce clogging

- Available with ANSI flange construction hoses or Bauer ends

- Designed to withstand impact, vibration, and flex fatigue at construction sites

These hoses perform reliably during tunneling works, shaft dewatering, slurry return lines, and abrasive material handling operations that exceed the tolerance of standard hoses.

Lay Flat Hose for Construction Dewatering & Temporary Water Transfer

Our heavy-duty lay flat hose range is designed for construction dewatering, flood control, site bypass systems, and temporary water movement. This flexible industrial hose for construction offers compact storage, fast setup, and long continuous lengths that reduce connection points and leak potential.

Key Advantages

- Construction dewatering hose with high tensile strength and kink resistance

- Lightweight for swift deployment and retrieval in fast-paced environments

- Smooth bore design ensuring efficient, unrestricted water transfer

- Long lengths ideal for trench dewatering and pump bypass systems

- Suitable for clean water, light slurry, and general site transfer

- Compatible with Bauer fittings, construction, quick-couplings, and manifolds

Lay flat hose is widely used for bypass pumping, emergency water redirection, site drainage, trench dewatering, and portable water movement on remote construction sites.

Speak With Technical Team

Get in touch with Anaconda Pipe & Hose for industry-ready pipe and hose solutions.

Built for Abrasion, Corrosion & High-Pressure Demands in Construction

All Anaconda products are engineered to withstand abrasion, UV exposure, dragging, flexing, impact, and continuous high-pressure duty cycles common in construction. Our solutions deliver:

- Longer service life

- Lower replacement frequency

- Reduced maintenance labor

- Improved handling safety

- Better compatibility with existing construction hydraulic equipment and hose systems.

These factors make Anaconda a preferred supplier for construction contractors seeking durable, long-lasting fluid-handling infrastructure.

Product Comparison: Construction Pipe & Hose Solutions

Criteria | HDPE Pipe | Slurry Hose | Lay Flat Hose |

|---|---|---|---|

Primary Use | Permanent or semi-permanent water, dewatering mains, and utility lines | High-abrasion, high-pressure slurry movement | Temporary water transfer & dewatering |

Abrasion Resistance | Moderate | Very high | Moderate |

Corrosion Resistance | Excellent | High (linear dependent) | Moderate to high |

Pressure Capacity | Medium to high | High | Medium |

Flexibility | Moderate | High bend tolerance | Very high |

Installation | Lightweight and easy to install | Heavier; may require equipment | Very lightweight & fast deployment |

Connection Options | Bauer, mechanical couplings, fusion, flanged | ANSI flanges, Bauer ends | Bauer, quick couplings |

Typical Uses | Water supply, drainage, bypass, utilities | Drilling slurry, dredging, aggregate movement | Dewatering, flood control, and bypass pumping |

Need Help Selecting the Right Construction Pipe or Hose?

Case study

Enhancing Construction Site Water Handling Efficiency with Anaconda Systems

Client Profile

A large civil contractor working on a multi-phase infrastructure project involving excavation, tunneling, and continuous dewatering operations

Challenge

The site faced recurring issues:

- Frequent hose failures due to abrasion from sand & aggregates

- Corrosion in metal pipes is causing downtime

- Slow deployment of temporary bypass systems

- High maintenance labor and repeated material replacement

- Difficulty integrating mixed fittings and non-standard hoses

The team needed a robust, standardized solution for water transfer, slurry movement, and temporary bypass lines.

Solution Provided

- HDPE Pipe installed as the main dewatering and utility distribution line due to its corrosion resistance and low maintenance needs.

- Slurry Hose is deployed at pump discharge points, tunneling slurry return paths, and aggregate-rich flow zones.

- Lay Flat Hose supplied for rapid-deployment bypass operations and trench dewatering.

Implementation Steps

- Replaced corroded steel runs with flexible HDPE construction pipe

- Installed ANSI-flanged slurry hose assemblies at slurry discharge pumps

- Prepared long-length lay flat hose kits for emergency bypass and temporary routing

- Standardized all connections to the Bauer fittings construction for field efficiency

Results Achieved

- Significant reduction in abrasion-related hose replacements

- Faster dewatering system setup and teardown

- Lower maintenance costs due to improved durability

- Streamlined compatibility across all transfer lines

- Improved uptime and reduced operational delays

Frequently Asked Questions

What type of pipe or hose is best for construction dewatering?

For continuous dewatering, lay flat hose for construction is typically preferred due to its lightweight handling, long continuous lengths, and fast deployment. For permanent or semi-permanent dewatering mains, HDPE pipes for construction provide better durability and lower lifecycle cost.

When should a slurry discharge hose be used on a construction site?

A slurry discharge hose is recommended when the fluid contains abrasive solids such as sand, silt, aggregate fines, drilling mud, or slurry generated from excavation and tunneling. It is more abrasion-resistant than standard water hoses and prevents premature failure.

What fittings are compatible with Anaconda’s hoses and pipes?

Our systems support Bauer fittings construction, ANSI flange construction hoses, and standard construction pipe fittings, ensuring compatibility with most pumps, manifolds, and bypass equipment used on construction sites.

Are HDPE pipes suitable for heavy equipment environments?

Yes. Industrial HDPE pipe provides excellent impact resistance and flexibility, allowing it to handle ground movement, uneven terrain, and vibration caused by construction equipment without cracking or corrosion.

How do I determine the right hose diameter for site pumping?

The correct diameter depends on flow requirements, pump size, discharge head, and solids concentration. Providing these parameters allows our engineering team to recommend the appropriate industrial construction hose or pipe specification.

Can a lay flat hose be used for slurry or only water?

While lay flat hoses are primarily used for clean water and dewatering, heavy-duty variants can handle light slurries. For high-solids or abrasive flow, a dedicated material transport hose or abrasion-resistant hose is recommended.

What is the expected service life of HDPE pipe in construction applications?

HDPE offers a long service life due to its corrosion-resistant construction. Actual lifespan depends on pressure cycles, UV exposure, installation method, and the media handled, but HDPE generally outperforms metal or PVC in field conditions.

Do slurry hoses require special installation practices?

Slurry hoses should be supported and routed to minimize sharp bends and external abrasion. Using the correct Bauer fittings construction or ANSI flanged ends ensures secure, leak-free connections under high-pressure and high-solids flow.

Can these products integrate with existing hydraulic hose construction equipment?

Yes. Our hoses and pipes are designed to integrate with common hydraulic, pumping, and bypass systems used in construction. Transition fittings can be supplied when linking to non-standard equipment.

Are these solutions suitable for remote or large-scale project sites?

Yes. Heavy-duty lay flat hose offers logistical advantages in remote areas, and flexible HDPE construction pipe supports quick installation with limited equipment. Slurry hoses withstand aggressive material transport in mining, tunneling, and large-scale infrastructure works.

Contact Anaconda Pipe & Hose

Speak with our experts to define the right solution for your project. Our team supports you from initial planning through execution.