Dredging Industry

Anaconda Pipe & Hose engineered HDPE pipe, industrial slurry hose, and flexible lay-flat hose provide high-performance conveyance systems for dredging operations across coastal, river, and port environments. Designed to handle abrasive slurries, long-distance discharge, and variable site conditions, our products support cutter suction dredgers, barge-mounted pumps, reclamation projects, and nearshore transport. Our systems prioritize abrasion resistance, long service life, and rapid mobilization to reduce downtime and lifecycle cost for contractors, mining operators, and marine engineering firms.

Home

Industries

DredgingWhy choose Anaconda Pipe & Hose for dredging applications

Anaconda delivers integrated hose and pipe systems that are field-proven in large-scale dredging, reclamation, sediment removal, port deepening, and inland waterway maintenance. Our product range is built around three essential requirements for dredging:

- Consistent, high-volume slurry flow

- Superior abrasion and pressure resistance

- Quick assembly, flexible routing, and reduced operational interruptions

HDPE pipe ensures long-run stability, slurry hose manages high-wear discharge and suction zones, and lay-flat hose provides rapid-deploy options for temporary flows and support lines. The result is a cohesive dredge conveyance system suitable for harsh marine and river environments.

Industrial Slurry Hose for high-wear dredging environments

Use cases: pump discharge, suction hose on cutter suction dredgers, flexible connections near elbows, joints between floating pipelines, barge-to-shore transitions.

Key features

- Abrasion-resistant inner lining engineered for sand, gravel, silt, and high-density slurry.

- Reinforced textile layers and helical steel wire for structural integrity under pressure, movement, and vacuum conditions.

- Heavy-duty flanged ends compatible with dredge pumps, HDPE pipeline connections, and standard marine fittings.

Advantages for dredging

- Performs reliably in the most abrasive areas of the flow path.

- Suction and discharge models available, depending on vacuum and pressure requirements

- Flexible while maintaining a defined bend radius, preventing kinking during vessel repositioning.

Role in a dredging system

Paired with HDPE discharge mains, the slurry hose creates a complete slurry movement solution capable of handling both continuous operation and dynamic dredging movements.

HDPE Pipe for dredging discharge lines

Use cases: long-distance discharge runs, floating pipelines, beach nourishment lines, barge-to-shore transfer, reclamation placement.

Key features

- Available in DR11 and DR17 wall classes (pressure classes) to meet pressure, stiffness, and buoyancy requirements in dredging.

- Smooth bore interior minimizes friction loss, improving pump output and energy efficiency during long-distance slurry transport.

- Excellent abrasion and corrosion resistance suited to seawater, sediment, and high solids content.

- Strong structural integrity for use with floats, pontoons, or buried shoreline sections.

Advantages for dredging

- Long service life under harsh marine conditions.

- Lightweight compared to steel, enabling faster installation, towing, and handling.

- Reduced leak points due to longer pipe lengths and secure jointing options.

Typical specifications

Available in multiple diameters used in dredging discharge lines, with options for flanged ends, stub-ends, and connections to pump manifolds or slurry hose assemblies.

Lay Flat Hose for temporary lines and rapid deployment

Use cases: temporary bypasses, dewatering, return-water routing, flushing lines, support operations around dredge pumps.

Key features

- Collapsible design allows compact storage onboard dredgers and support vessels.

- Lightweight construction enables quick setup and rapid relocation.

- UV-resistant and suitable for repeated outdoor use.

Advantages for dredging

- Ideal for short-term pumping tasks where fast mobilization matters.

- Integrates easily with portable pump skids and auxiliary systems.

- Cost-effective and easy to manage in dynamic marine environments.

System-level benefits for dredging operations

Integrated slurry movement

HDPE pipe provides stable long-run transport, slurry hose manages high-wear connection zones, and lay-flat hose supports temporary or supplementary flows.

Reduced downtime

Quick-fit connections and modular assemblies reduce installation and change-out time during repositioning or maintenance.

Abrasion and corrosion resistance

Material selection ensures long service life even under continuous exposure to saltwater, sediment, and high-pressure slurry.

Operational flexibility

Adaptable to cutter suction dredgers, bucket dredgers, barge-mounted pumps, reclamation activities, and inland sediment-removal operations.

Speak With Technical Team

Get in touch with Anaconda Pipe & Hose for industry-ready pipe and hose solutions.

Typical dredging applications

- Shore discharge lines for reclamation

- Floating pipeline connections between the dredger and the shore

- Suction and discharge hoses on cutter heads

- Sediment and sludge removal from rivers, lakes, and ports

- Beach nourishment and land development

- Temporary water and slurry transfer alongside marine operations

Dredging Hose & Pipe Solutions

Product Comparison Table

Category | HDPE Pipe | Industrial Slurry Hose | Lay Flat Hose |

|---|---|---|---|

Primary Application | Long-distance slurry discharge, floating pipelines | Suction and discharge in abrasive zones | Temporary water movement and bypass |

Best Used For | Continuous high-volume flow lines | High-wear pump discharge and suction areas | Rapid deployment and short-term routing |

Strengths | Low friction, corrosion resistance, long service life | High abrasion resistance, reinforced for pressure and movement | Lightweight, easy to deploy and relocate |

Abrasion Resistance | Good for long straight runs | Excellent for heavy solids | Moderate for clean water or light slurry |

Pressure Handling | Depends on DR rating, suitable for dredge discharge | Suitable for suction and discharge in demanding conditions | Suitable for moderate pressure |

Flexibility | Rigid but installable in long lines | Flexible with reinforced structure | Highly flexible |

Fittings Available | Flanged ends, stub-ends | Heavy-duty flanges | Bauer, camlock, hose-tail |

Durability in Dredging | Excellent for corrosive and abrasive marine environments | Excellent for high abrasion and vibration zones | Good for temporary or auxiliary duty |

Installation Speed | Fast with modular pipe lengths | Moderate due to weight and reinforcement | Very fast deployment and recovery |

Mobility | Low once installed | Medium mobility | Very high mobility |

Cost Efficiency | High long-term value | High durability for demanding use | Most economical for temporary lines |

Note: Actual pressure/vacuum ratings depend on diameter, DR, and hose construction. Confirm with engineering.

Case study

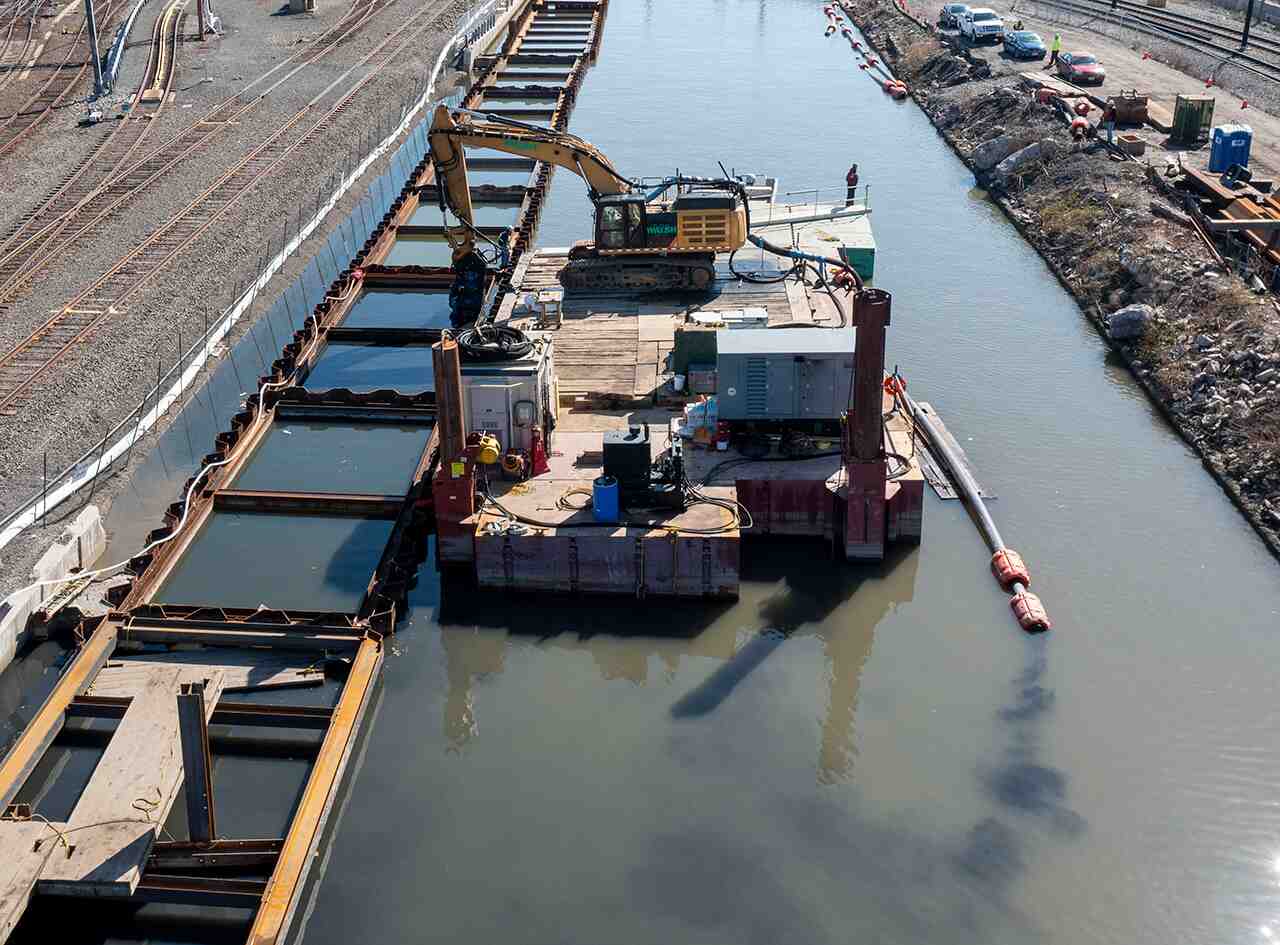

Delivering reliable slurry transport for a coastal dredging project

Client Overview

A marine civil contractor was tasked with extending a port channel and transporting large volumes of sand to a reclamation site nearly one kilometer away. The project required a slurry conveyance system capable of handling high abrasion, movement of floating pipelines, and rapid assembly in shifting tidal conditions.

Project Challenge

The contractor needed:

- A durable discharge line for long-distance slurry transport

- High-wear components near the dredge pump capable of handling constant movement

- Temporary water-transfer lines to manage return water during operations

- Fast installation to meet a tight dredging window

Existing hoses on the dredger showed significant wear, and previous steel pipeline sections required frequent maintenance, creating risk of downtime.

Implementation and Performance

The full pipeline system was installed in less than two days.

Outcomes included:

- Stable slurry movement with no leakage incidents

- Zero hose failures despite continuous heavy solids pumping

- Reduced fuel consumption due to improved hydraulic efficiency

- Faster work cycles thanks to simplified hose handling

Anaconda Pipe & Hose Solution

Anaconda Pipe & Hose supplied a complete dredging conveyance package consisting of HDPE pipe, slurry hose, and lay flat hose.

1. HDPE Pipe for Main Discharge Line

DR17 HDPE pipe was deployed along the floating and land sections. Its smooth bore improved pump efficiency and reduced head loss, while its corrosion and abrasion resistance ensured uninterrupted flow.

2. Slurry Hose for High-Abrasion Zones

Industrial slurry hose was installed at the pump outlet and at pipeline transitions. The reinforced construction supported suction and discharge forces, absorbed vessel movement, and eliminated premature hose failures.

3. Lay Flat Hose for Return Water and Support Lines

Heavy-duty lay flat hose enabled quick rerouting of return water and served as temporary piping during dredger repositioning. Its portability minimized delays.

Results

- Project completed ahead of schedule

- Lower maintenance cost throughout operations

- Consistent dredging output even in high abrasion conditions

- Positive contractor feedback on ease of connections and durability

Technical support and customization

Anaconda Pipe & Hose provides:

- DR-rated HDPE sizing selection

- Custom slurry hose lengths and flange options

- Lay-flat hose assemblies for rapid deployment

- Engineering support for pump curve matching, abrasion life planning, and floating pipeline configuration

Our team can assist with drawings, hydraulic considerations, and material lists tailored to dredging workflows.

Frequently Asked Questions

What pipe and hose solutions does Anaconda Pipe & Hose recommend for dredging applications?

Anaconda recommends using HDPE pipe for long-distance discharge lines, industrial slurry hose for high-abrasion suction and discharge points, and lay-flat hose for temporary or rapidly deployable water transfer requirements.

Why is HDPE pipe widely used in dredging discharge systems?

HDPE pipe provides low friction, high abrasion resistance, corrosion resistance in marine environments, and long continuous lengths that reduce leak points. Its durability and smooth bore make it effective for transporting sand, silt, and slurry over long distances.

Can Anaconda slurry hose handle heavy solids and abrasive dredge material?

Yes. Industrial slurry hose is designed with abrasion-resistant liners and reinforced structure to handle sand, gravel, silt, and high-density slurries. It performs reliably in both suction and discharge roles commonly found on dredging vessels.

How does lay-flat hose support dredging projects?

Lay flat hose offers fast deployment for temporary bypass lines, return-water routing, flushing lines, and auxiliary flows. It is lightweight, easy to store, and ideal for short-term operations where mobility is required.

Are Anaconda Pipe & Hose products compatible with standard dredging pumps and fittings?

Yes. HDPE pipe and slurry hose can be supplied with flanged ends that interface with dredge pumps and pipeline systems. Lay-flat hose is available with Bauer, camlock, and hose-tail fittings for compatibility with portable pumps and support equipment.

Can these products be used in both marine and inland dredging operations?

Absolutely. The materials and construction are suited to coastal dredging, river and lake sediment removal, port deepening, reclamation projects, and inland waterway maintenance.

What factors determine whether to use HDPE pipe or slurry hose?

HDPE pipe is ideal for long, straight discharge runs requiring low friction and high durability. Slurry hose is preferred near the dredge pump, at bends, transitions, or anywhere flexibility and abrasion tolerance are essential.

How quickly can Anaconda Pipe & Hose systems be installed on a dredging project?

HDPE pipe is delivered in modular lengths for fast joining, while slurry hose and lay flat hose allow quick connections around pump interfaces and temporary routes. Contractors often assemble full discharge lines within hours or a few days, depending on length.

Can Anaconda provide custom lengths or configurations for dredging pipelines?

Yes. HDPE pipe, slurry hose, and lay flat hose can be supplied in custom lengths with selected fittings, flange types, and reinforcement levels tailored to project specifications and pump performance.

Are these hoses and pipes suitable for floating pipeline systems?

Yes. HDPE discharge lines are commonly fitted with floats for use as floating pipelines. Slurry hose sections are used near the dredger and at pipeline joints to absorb movement and vibration. Lay-flat hose may also support temporary floating routes for water transfer.

How do these products perform under continuous high-pressure conditions?

HDPE pipe withstands sustained discharge pressures based on its DR rating, while slurry hose is reinforced for both suction and discharge loads. Both products maintain structural integrity under the high-pressure cycling common in dredging operations.

Do these solutions reduce maintenance requirements in dredging operations?

Yes. The abrasion-resistant construction, corrosion-proof materials, and reduced number of joints help minimize wear, leaks, and downtime. This leads to lower lifetime maintenance costs and more reliable dredging cycles.

Contact Anaconda Pipe & Hose

Speak with our experts to define the right solution for your project. Our team supports you from initial planning through execution.