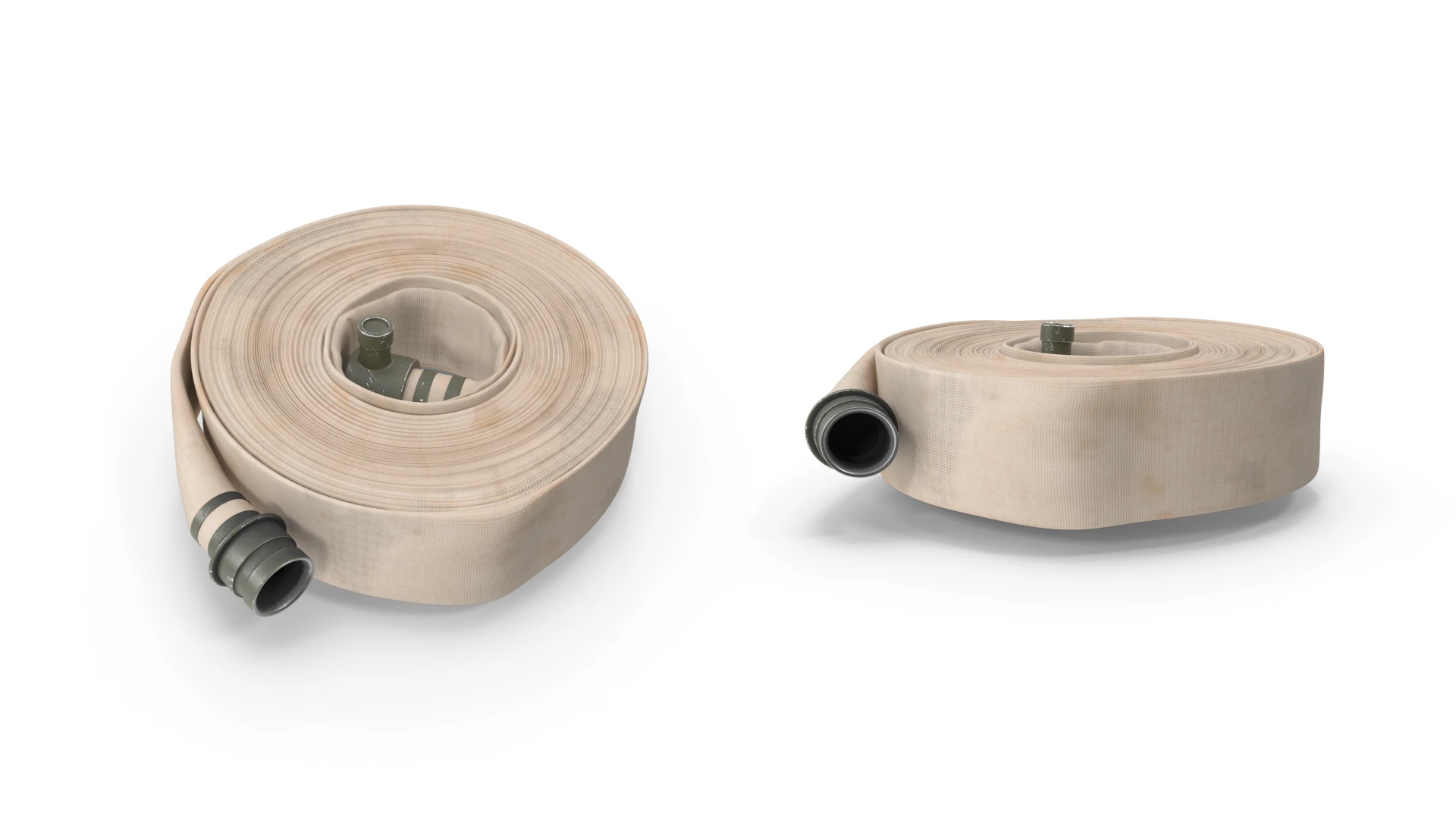

WAT-Hog Lay Flat Hose

WAT-Hog is a high-strength lay flat hose engineered for fuel, wastewater, and water transfer. It features a through-the-weave one-piece construction with high-tenacity polyester reinforcement encapsulated in polyurethane for abrasion, chemical, and UV resistance. Designed for high flexibility, kink resistance, rapid deployment, and long service life in municipal, industrial, marine, and military operations.

Home

Lay Flat Hose

WAT-Hog Lay Flat HoseEngineered for Operational Efficiency and Field Durability

Through-the-Weave One-Piece Construction Hose

High-tenacity circular woven polyester fully encapsulated in polyurethane ensures structural integrity, pressure stability, and zero delamination.

Long Service Life in Harsh Environments

Resistant to abrasion, cutting, fuels, chemicals, UV, ozone, weathering, hydrolysis, and microbiological attack, eliminating corrosion, scaling, and frequent replacements.

Flexible, Kink-Resistant Hose & Terrain Adaptive

Maintains flow without kinking and follows uneven ground contours without stressing the pipeline, and avoids costly trenching or path cutting.

Low Pressure Loss & High Flow Performance

Swells up to maximum operating pressure to increase volume capacity, supporting faster, more efficient transfer with lower pumping energy.

Quick Deployment & Retrieval

Supports long continuous lengths and is compatible with reels, trailers, and deployment systems, reducing setup time, labor, and connection points.

Optional Static Discharge Safety for Fuel Transfer

Available with MIL-PRF-370 Type C bonding wires. Required when pumping fuels. Consult the site safety officer for safe grounding during fuel operations.

Compact Storage & Transport Ready

Coils without permanent deformation retain performance after long-term storage.

Hardware Integration Ready

Compatible with manifolds, couplings, and auxiliary equipment for modular system design

Technical Specifications

WAT-Hog lay flat hose is engineered for high-pressure fluid transfer across industrial, municipal, marine, and military operations. It features:

- Construction: Through-the-weave, one-piece circular woven high-tenacity polyester reinforcement encapsulated in polyurethane lining and cover.

- Operating Fluids: Fuel, wastewater, treated/reclaimed water, slurry, and industrial fluids.

- Working Pressure: Up to 300 psi (2068.43 kPa) depending on size.

- Burst Pressure: Up to 600 psi (4136.85 kPa).

- Expansion: Swells up to 10% above nominal diameter under max pressure to improve flow.

- Static Bonding Option: Available with MIL-PRF-370 Type C static discharge wires for fuel transfer.

- Standards: Built for long-term deployment, corrosion-free, UV, and chemical-resistant performance.

WAT-Hog Specifications

Contact us for quotes, bulk supply options, or compatibility guidance with existing infrastructure.

Hose Size (inch) | Hose Size (mm) | Working Pressure (psi) | Burst Pressure (psi) | Wall Thickness (inch) | Weight (lbs/ft) |

|---|---|---|---|---|---|

2 | 51 | 300 | 600 | 0.08 | 0.21 |

2½ | 64 | 300 | 600 | 0.08 | 0.30 |

3 | 76 | 300 | 600 | 0.09 | 0.37 |

4 | 102 | 300 | 600 | 0.09 | 0.56 |

6 | 152 | 300 | 600 | 0.10 | 1.22 |

7¼ | 184 | 250 | 500 | 0.16 | 1.89 |

8 | 200 | 250 | 500 | 0.18 | 2.10 |

10 | 250 | 250 | 500 | 0.20 | 2.85 |

Speak With Technical Team

Get in touch with Anaconda Pipe & Hose for industry-ready pipe and hose solutions.

Related Products

Aqua Guard Lay-Flat Hose

A high-performance TPU hose for potable water transfer in industrial and municipal settings. Built with through-the-weave thermoplastic polyurethane and high-tenacity circular woven polyester reinforced hose; certified to NSF61; rated for working pressures up to 300 psi (for 2″- 6″ sizes) and burst up to 600 psi.

Armour Guard Lay-Flat Hose

A water-discharge Heavy-Duty Lay Flat Hose built for oil-field and industrial use. Constructed of nitrile/PVC blend extruded through high-performance synthetic materials, with ozone-resistant synthetic rubber liner and cover, rated at 300 psi service pressure and 900 psi burst (for 1½″ and 2½″ diameters).

Aqua Guard vs Armour Guard vs Wat-Hog

Product Comparison

Parameter | WAT-Hog | Aqua Guard | Armour Guard |

|---|---|---|---|

Primary Use | Fuel, wastewater, sewer, and treated water transfer | Potable water transfer | Heavy-duty industrial water discharge |

Construction Type | Through-the-weave, one-piece polyurethane extrusion | Through-the-weave, one-piece polyurethane extrusion | Heavy-duty nitrile PVC blend, extruded through the weave |

Reinforcement | Circular woven high-tenacity polyester | Circular woven high-tenacity polyester | High-tensile synthetic yarn |

Cover & Liner Material | Elastomeric polyurethane (TPU) | Elastomeric polyurethane (TPU) | Nitrile PVC blend |

Certification / Compliance | Bonding wires option (MIL-PRF-370 Type C) | NSF61 Certified | __ |

Working Pressure | 300 psi (2–6″) / 250 psi (7¼–10″) | 300 psi (2–6″) / 250 psi (7¼–10″) | 300 psi (1½–2½″) |

Burst Pressure | 600 psi (2–6″) / 500 psi (7¼–10″) | 600 psi (2–6″) / 500 psi (7¼–10″) | 900 psi |

Wall Thickness | 0.08″ – 0.20″ (2.03 – 5.08 mm) | 0.08″ – 0.20″ (2.03 – 5.08 mm) | Not specified |

Weight (per ft) | 0.21 – 2.85 lb (0.095 – 1.29 kg) | 0.21 – 2.85 lb (0.095 – 1.29 kg) | 0.28 to 0.52 lb (0.13 to 0.24 kg) |

Color | Blue/Tan/Orange | Blue / Tan | Black |

Resistance Properties | Abrasion, fuels, chemicals, UV, ozone, weathering, hydrolysis, microbiological attack | Abrasion, fuels, chemicals, UV, ozone, weathering, hydrolysis, microbiological attack | Ozone, abrasion, heat, fuels, oil, chemicals |

Additional Features | Optional static discharge wires; fast deployment and retrieval | Long service life; fast deployment and retrieval | Anti-burst design; easy storage |

Typical Applications | Municipal, industrial, marine, and military fuel/water transfer | Municipal & military potable water systems | Industrial discharge and dewatering |

Pipe & Hose Rentals: WAT-Hog

WAT-Hog hoses are available for rental for temporary fuel, water, or wastewater transfer in municipal, industrial, marine, and military operations. Pre-tested lengths, quick coupling options, and deployment equipment can be supplied as needed.

Need it on-site?

Built for Demanding Industries/ Engineered for Multi-Industry Performance

Municipal & Public Works

Ideal for sewer bypass operations, wastewater transfer, stormwater control, emergency water supply, and routine sewer maintenance. Its flexibility eliminates the need for trenching or rigid pipe infrastructure during temporary bypass projects.

Water & Utilities

Used for high-flow water supply, treated or reclaimed water distribution, groundwater extraction, and dewatering tasks in utility networks. The hose’s low pressure loss and quick deployment make it suitable for short-term and seasonal utility operations.

Industrial & Manufacturing

Supports cooling water transfer, chemical-compatible process water movement, temporary plant bypass lines, and general fluid management in factories and production units. It withstands continuous-duty operation and abrasive environments.

Construction & Dredging

Deployed for construction site dewatering, slurry transfer, dredged material discharge, cofferdam bypass systems, and temporary fluid handling where rapid setup and relocation are essential. The hose performs well on uneven terrain and under heavy machinery traffic.

Mining & Quarrying

Used for pit and shaft dewatering, mine water transfer, tailings and slurry movement, and dust suppression systems. Its high durability and abrasion resistance make it suitable for harsh, mobile operations in open-pit and underground mines.

Energy, Power & Fuel

Applicable in power plant cooling water circulation, temporary pump-around systems, oilfield water transfer, and fuel distribution when equipped with static discharge wires. Suitable for both maintenance bypass and field-based energy operations.

Military & Defense

Used for quick deployment of fuel and water supply lines during field missions, tactical base operations, disaster relief, and mobile command setups. Lightweight and flexible design enables fast transport and retrieval.

Marine, Offshore & Shipbuilding

Employed for ship-to-shore water or fuel transfer, deck and ballast systems, cargo fluid handling, and offshore platform supply operations. Corrosion resistance and flexibility make it ideal for coastal and marine environments.

Agriculture & Fisheries

Adapted for high-volume irrigation, pond or canal discharge, livestock and farm water supply, hatchery circulation, and aquaculture fluid movement. It withstands UV exposure, fertilizers, organic matter, and long outdoor use.

Case study

WAT-Hog Deployed for Municipal Sewer Bypass Operation

Project Overview

A 2.8 km section of the city’s aging sewer line required structural rehabilitation. To maintain uninterrupted waste transfer, the municipality needed a temporary bypass pipeline capable of handling high flow rates, variable terrain, and 24/7 operation for 30+ days. Traditional rigid pipes were ruled out due to extended setup time, high installation cost, and the need for surface trenching.

Challenge

- Continuous high-volume sewage transfer (2,500–3,200 GPM)

- Operation across uneven and traffic-heavy urban terrain

- Requirement for rapid setup to minimize service interruption

- No allowance for ground excavation or permanent fittings

- Need for low maintenance and leak-free performance

Solution: Why WAT-Hog was Selected

The contractor deployed WAT-Hog industrial lay flat hose in continuous lengths, connected to diesel bypass pumps and existing manholes. The hose’s through-the-weave polyurethane construction ensured flexibility, pressure stability (up to 300 psi), and resistance to chemicals, abrasion, and microbial attack.

Implementation

- Total Hose Length Installed: 1.9 km (6″, 8″, and 10″)

- Deployment Time: 6 hours using lightweight reels and flaking boxes

- Connectors Used: Camlock couplings and aluminum manifolds

- Support Hardware: Hose ramps for road crossings, grounding wires for static discharge in fuel-powered pumps

Results

With the help of the WAT-Hog system, the contractor reported that the setup was 60% faster than for conventional rigid HDPE pipelines. Over 32 days of continuous operation, the hose maintained stable flow with zero leaks, ruptures, or failures. Pressure loss remained below four psi per 100 feet, ensuring efficient pumping throughout the bypass. No maintenance or replacements were required during the project, and overall labor and installation costs were reduced by approximately 28%. The municipality reported improved deployment efficiency and operational reliability using WAT-Hog for temporary bypass work.

Frequently Asked Questions

What is the WAT-Hog hose primarily used for?

WAT-Hog is designed for high-volume transfer of fuel, wastewater, sewage, treated and reclaimed water. It is widely used in municipal bypass systems, industrial dewatering, mining pits, marine supply lines, and military fuel or water delivery operations.

What makes WAT-Hog different from standard lay flat hoses?

Unlike conventional lay flat hoses that are layered or glued, WAT-Hog industrial lay flat hose uses a through-the-weave, one-piece construction. The polyester reinforcement is fully encapsulated in polyurethane, eliminating delamination and providing superior durability, flexibility, and long-term service life.

Is the hose suitable for fuel transfer, and is it safe?

Yes. WAT-Hog is compatible with fuel transfer applications. For added safety, it can be supplied with static discharge bonding wires compliant with MIL-PRF-370 Type C to prevent electrical buildup during fuel movement.

What are the pressure ratings for different sizes?

The hose offers working pressures up to 300 psi for 2″–6″ sizes and 250 psi for larger diameters such as 7¼”, 8″, and 10″. Burst pressure reaches 600 psi for smaller sizes and 500 psi for larger ones, ensuring a solid safety margin.

Can the hose be installed on uneven or rough terrain?

Yes. Its flexibility and kink resistance allow WAT-Hog to follow natural ground contours without trenching or ground levelling. This significantly reduces installation time and eliminates the need for surface modification.

How resistant is it to environmental and chemical exposure?

The polyurethane encapsulation provides resistance to abrasion, cutting, fuels, many industrial chemicals, UV rays, ozone, hydrolysis, and microbiological damage. It does not corrode, scale, or degrade in harsh outdoor environments.

Which industries commonly deploy WAT-Hog hoses?

It is used across municipal water and sewer departments, industrial plants, mining sites, dredging operations, marine and shipbuilding sectors, energy and power generation, agriculture, fisheries, manufacturing facilities, and military field logistics.

What sizes and configurations are available?

WAT-Hog is available from 2″ to 10″ diameters. Each size is manufactured to defined working and burst pressures, wall thickness, and weight specifications as noted in the technical data sheet.

Is it easy to transport and store?

Yes. It can be coiled compactly and stored long-term without losing performance. The Flexible Lay Flat Hose retains its flexibility after storage and is lighter than rigid pipe alternatives.

How is the hose deployed on-site?

WAT-Hog can be easily deployed using hose reels, flaking boxes, trailers, or power-driven retrieval systems. Fewer coupling points mean quicker installation and reduced leak risks.

What fittings and accessories can be supplied with it?

A full range of couplings, manifolds, reducers, and connection hardware is available to integrate WAT-Hog into pump systems, multiple wastewater transfer hose sections, or bypass networks.

Does the hose expand under pressure, and is that a concern?

The fuel transfer hose is designed to expand up to approximately 10% over its uncharged diameter at maximum pressure. This controlled swell increases water flow capacity and reduces friction loss without compromising structural integrity.

Contact Anaconda Pipe & Hose

Speak with our experts to define the right solution for your project. Our team supports you from initial planning through execution.