Flat hoses are versatile, durable, and indispensable tools across various industrial sectors. Their unique design and functionality make them a preferred choice for numerous applications, ranging from dewatering in construction to irrigation in agriculture. In this article, we delve into what flat hoses are, their key features, and how they’re used in industrial applications.

What Is a Flat Hose?

Flat hose is designed to offer a unique combination of efficiency, convenience, and versatility in liquid transfer applications. Here’s an expanded explanation:

Construction and Design

The flat hose is made from durable materials like PVC, rubber, or TPU (thermoplastic polyurethane). These materials provide resistance to wear, abrasion, and harsh environmental conditions, making the hoses long-lasting even in demanding applications.

- Collapsible Design: The defining feature of the flat hose is its ability to lay completely flat when not in use. This design minimizes their volume, making storage and transportation much easier than traditional hoses.

- Reinforced Construction: A lay flat hose includes reinforcement layers, such as braided or woven fibers, which enhance their tensile strength and pressure-handling capabilities.

Advantages Over Traditional Hoses

- Lightweight and Flexible: Unlike rigid hoses, the flat hose is lightweight, allowing for easier handling and deployment. Their flexibility ensures they can navigate tight spaces and uneven terrains with ease.

- Reduced Kinking: Kinking is a common issue with traditional hoses that disrupt the flow. The flat hose is specifically designed to minimize kinking, ensuring a consistent liquid transfer.

- Efficiency in High-Volume Applications: A Lay flat hose, in particular, is optimized for transferring large volumes of water or other liquids efficiently, making it ideal for irrigation, firefighting, or industrial dewatering.

Performance in Challenging Environments

Flat hose is adaptable to a variety of settings, such as:

- High Temperatures: Certain flat hose is engineered to withstand extreme heat, making them suitable for firefighting and industrial processes.

- Chemical Resistance: TPU-based hoses are particularly effective in handling chemicals, oils, and abrasive materials without degradation.

- Low Temperatures: Their flexibility is retained even in freezing conditions, making them useful in cold climates.

Applications

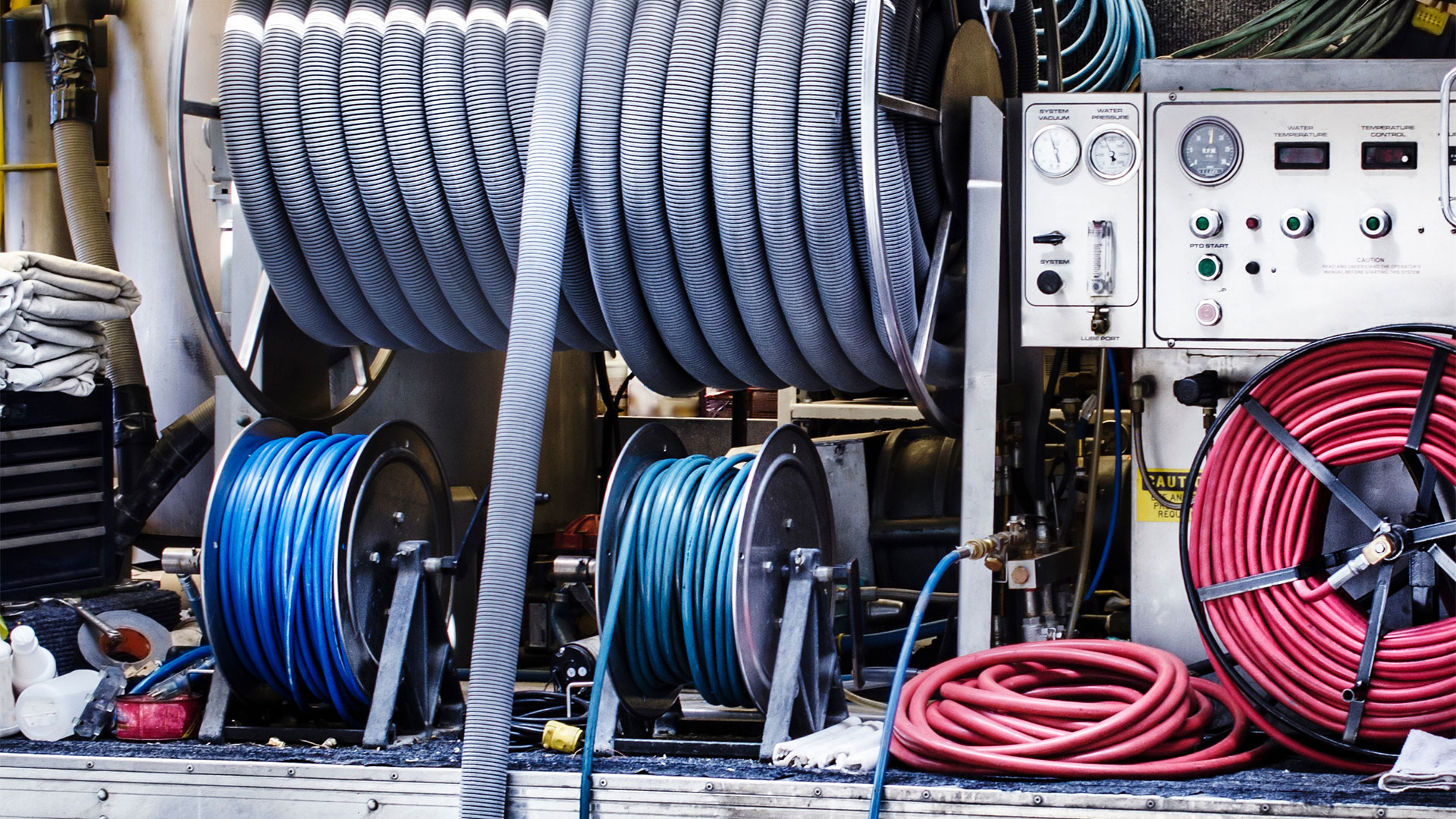

Flat hoses excel in industries where efficiency, reliability, and ease of use are paramount. They are commonly employed in:

- High-Pressure Systems: Their design accommodates systems that require robust, high-pressure performance.

- Tight Storage Spaces: Their compact nature when stored makes them a practical solution for facilities with limited storage space.

Key Features and Advantages of Flat Hoses

The flat hose provides a range of key features and advantages that are essential for efficient operations in various industrial settings. Here’s a deeper dive into these aspects:

- Lightweight and Portable

The collapsible design significantly reduces the weight of the flat hose compared to traditional hoses. This makes them extremely portable and easy to handle, especially in large-scale operations such as construction or firefighting. Workers can easily carry and deploy these hoses without requiring heavy machinery, making them practical in both urban and remote locations. - High Flexibility

Flat hoses can bend and adapt to different layouts without compromising performance. This flexibility is particularly beneficial when the hoses need to navigate tight spaces, uneven terrains, or winding paths. The ability to lay them out and retrieve them quickly streamlines operations, saving valuable time and reducing labor-intensive tasks. - Durability

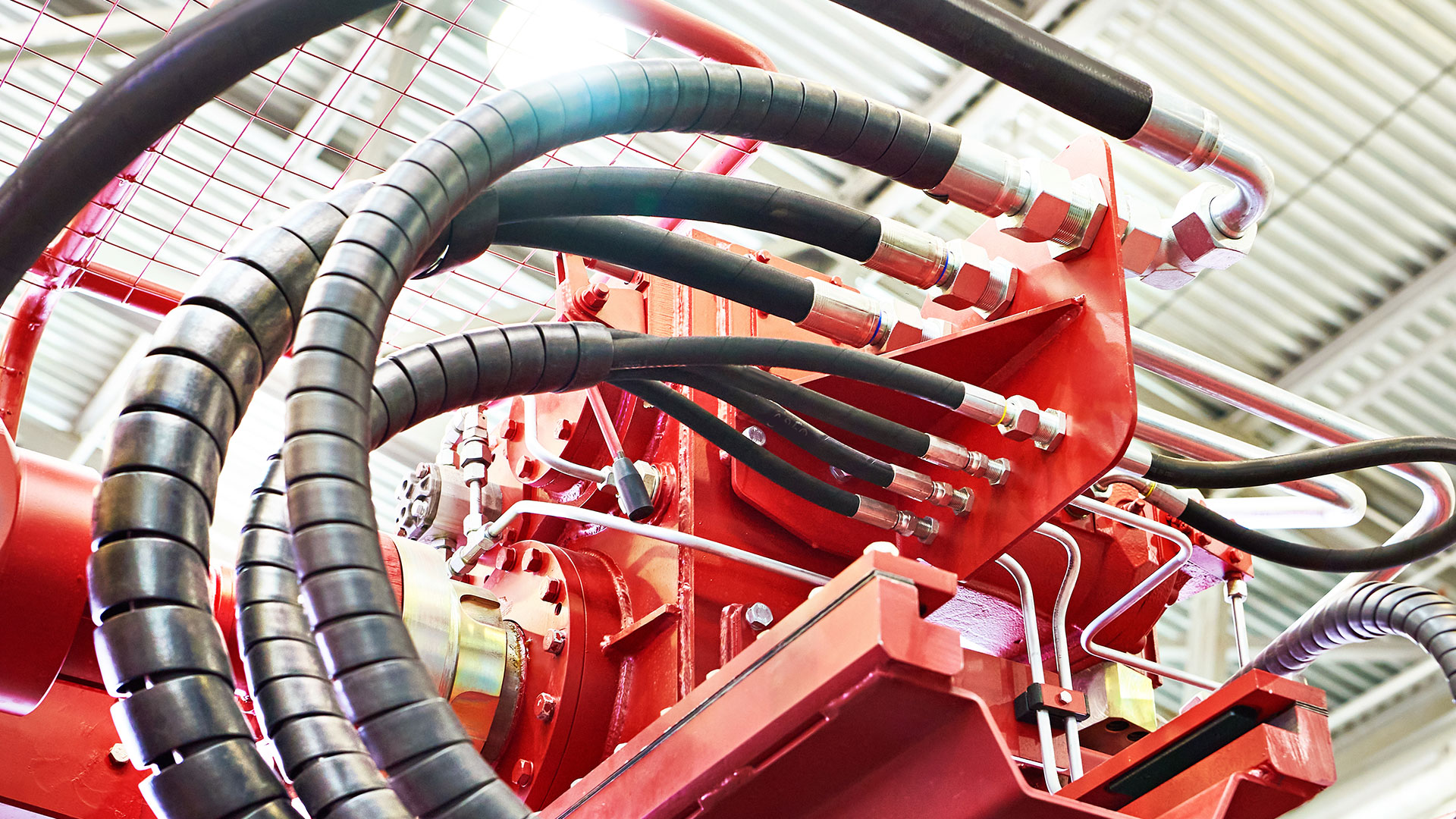

Constructed from tough materials like PVC, TPU, or rubber, the flat hose is built to withstand harsh environments. They are resistant to abrasion from rough surfaces, corrosion from chemicals, and general wear and tear. This durability ensures that the flat hose remains functional over prolonged use, even under demanding conditions. - High-Pressure Capacity

A lay flat hose is engineered to handle high-pressure demands, making it suitable for transferring water, slurry, or other materials over long distances. For industries like oil and gas or firefighting, this capacity is crucial for maintaining efficiency and ensuring the safety of operations. - Compact Storage

One of the most practical advantages of the flat hose is its ability to be rolled up or folded flat when not in use. This feature saves significant storage space compared to rigid hoses. It also makes transportation easier, allowing businesses to carry multiple hoses in a single vehicle or storage area. - Cost-Effectiveness

The long lifespan of the flat hose, coupled with their low maintenance needs, makes them a cost-effective solution. Their versatility across applications reduces the need for multiple specialized hoses, further contributing to cost savings. - Efficient Large-Volume Transfers

Lay flat hose is particularly designed for high-volume water or slurry transfers. Their ability to handle significant quantities with minimal leakage or resistance showcases their efficiency. This makes them indispensable for large-scale operations like agricultural irrigation or dredging projects.

By combining these features, flat hose provides unparalleled utility, enhancing productivity and reducing operational challenges in industrial applications. I can further elaborate on their specific uses or provide examples of industries where these features are critical. Let me know!

Common Industrial Applications

Flat hose is used in a wide range of industrial applications due to their adaptability and performance. Here are some of the most common uses:

1. Dewatering and Dredging

The flat hose is pivotal in dewatering and dredging projects due to its ability to transport large volumes of water, slurry, or sediment efficiently.

- Dewatering: Flat hose is often employed in construction and mining to remove excess water from sites. Their high-pressure capacity ensures quick and consistent water removal, which is crucial for maintaining safety and productivity in these environments.

- Dredging: Dredge hose, a type of flat hose, is specifically designed for heavy-duty dredging operations. They transport sediment, sand, or slurry extracted from riverbeds, harbors, and coastal areas. The durability of these hoses allows them to endure abrasive materials, ensuring minimal wear during prolonged use.

2. Agriculture

Flat hoses are indispensable in agriculture for efficient irrigation and chemical application.

- Irrigation Systems: Lay flat hose is commonly used to distribute water across large fields. Their lightweight design makes them easy to deploy and move around, even in remote or uneven terrain.

- Fertilizer and Pesticide Application: Flat hoses provide a reliable means of delivering liquid fertilizers or pesticides uniformly, ensuring optimal crop yield. Their resistance to chemical corrosion extends their lifespan, making them a cost-effective solution for farmers.

3. Construction

Construction sites often deal with challenges like flooding, mud, and water accumulation.

- Site Dewatering: Flat hoses are used to pump out standing water from excavation sites, foundations, or trenches, enabling work to continue uninterrupted.

- Flood Control: During heavy rains or in flood-prone areas, a lay flat hose provides quick water evacuation, protecting equipment and structures.

- Handling Contaminated Water: Flat hoses designed for rugged use can safely handle muddy or debris-filled water, minimizing damage to the equipment and ensuring smooth operation in adverse conditions.

4. Firefighting

Firefighting demands equipment that is both reliable and quick to deploy; a role flat hose fulfills perfectly.

- Quick Deployment: The collapsible and lightweight design allows firefighters to deploy the flat hose rapidly, saving critical time during emergencies.

- High-Pressure Delivery: Flat hose can withstand the high pressure required to pump water over long distances and heights, ensuring an effective response to large-scale fires.

- Durability in Harsh Conditions: These hoses are built to endure extreme heat, rough handling, and exposure to various terrains, maintaining performance in critical situations.

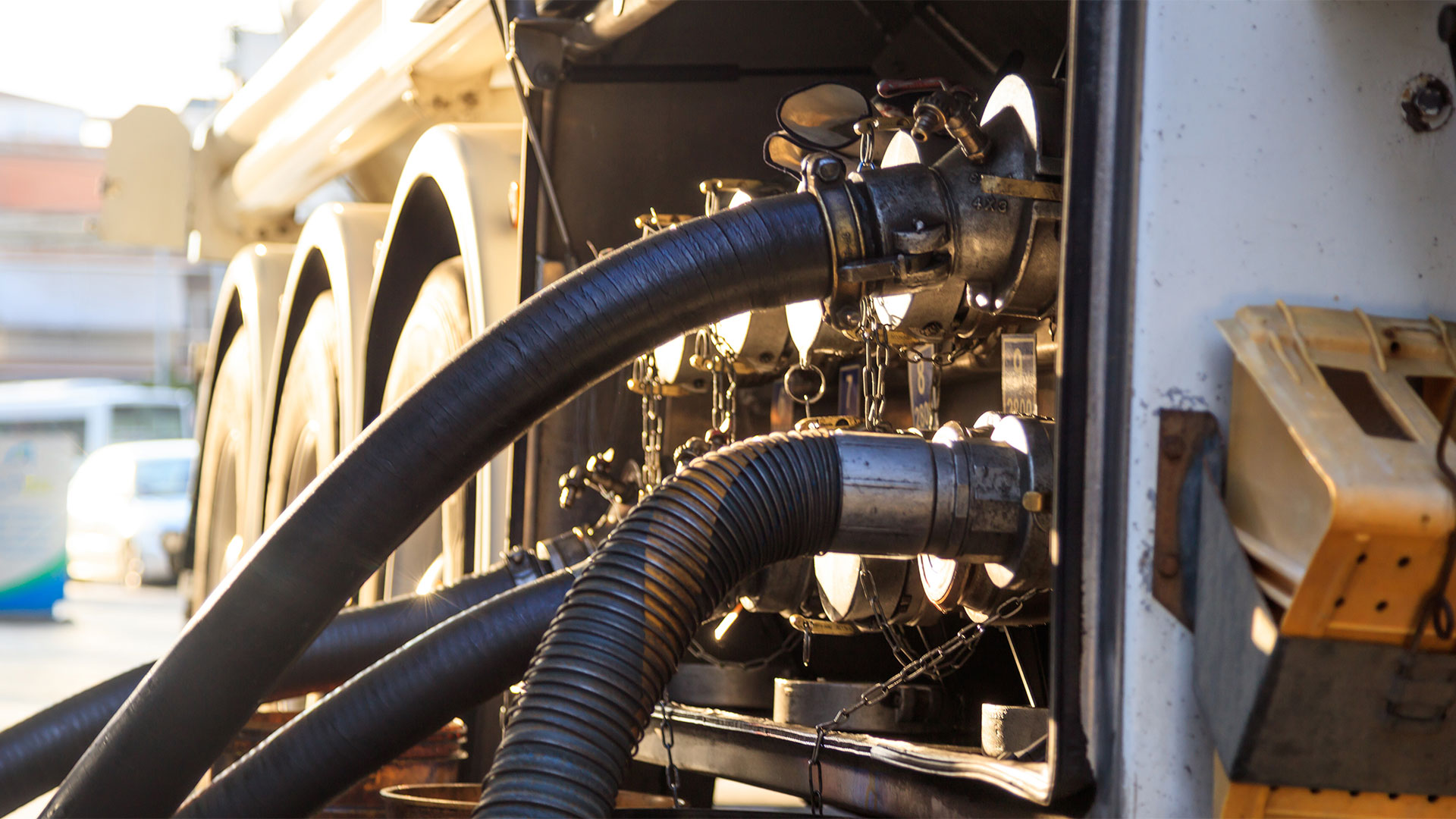

5. Oil and Gas Industry

In the oil and gas sector, the flat hose is vital for transferring liquids and handling harsh operational conditions.

- Liquid Transfer: A flat hose is used to transport chemicals, oil, and other fluids across refineries, pipelines, and storage facilities. Their chemical resistance ensures safe and efficient operations.

- Waste Management: The industry also uses flat and a dredge hose for disposing of waste products, such as drilling mud and wastewater.

- Heavy-Duty Applications: A Dredge hose handles abrasive materials and high-pressure demands in oil extraction or refining processes, demonstrating their ruggedness and adaptability.

Each application highlights the adaptability and resilience of lay flat hose, making them a valuable asset across diverse industrial sectors. If you’d like further information on any specific application or example, feel free to ask!

Choosing the Right Flat Hose for Your Needs

Selecting the right flat hose is critical for ensuring optimal performance and longevity. Here are some factors to consider:

- Material Compatibility: Different materials are suited for specific applications. For example, PVC hoses are ideal for water transfer, while TPU hoses are better for handling chemicals or abrasive materials. PVC is lightweight and cost-effective, while TPU offers enhanced strength and flexibility, making it suitable for tougher tasks.

- Pressure Rating and Diameter: The hose’s pressure rating and diameter determine its performance capabilities. High-pressure hoses are essential for applications like firefighting or transferring liquids over long distances, while larger diameters ensure higher flow rates. A dredge hose, in particular, are designed to handle high-pressure flows of abrasive materials effectively. Always match the hose’s specifications to your operational requirements to avoid inefficiencies or damage.

- Environmental Factors: Evaluate the conditions where the hose will be used. If it will be exposed to sunlight for extended periods, UV-resistant materials are necessary. Similarly, hoses used in cold climates should be capable of maintaining flexibility and performance at low temperatures. Terrain also matters—rugged environments may require reinforced hoses or a dredge hose to prevent punctures or tears.

- Manufacturer Reliability: Choosing a hose from a reputable manufacturer or distributor ensures you receive a product that meets industry standards. Reliable manufacturers also provide technical support and guidance to help you select the best flat hose or dredge hose for your needs, ensuring durability and performance.

Maintenance and Best Practices

Proper maintenance is key to extending the lifespan of a flat hose and ensuring its performance remains consistent. Here are some tips:

- Cleaning: Rinse the hose thoroughly after each use to remove debris and contaminants. For hoses used with chemicals, flush them with clean water to prevent corrosion. Neglecting to clean the hose can lead to clogging, material degradation, and reduced performance over time.

- Storage: Store the hose in a cool, dry place, away from direct sunlight or extreme temperatures. Roll or fold it neatly to prevent creases or damage. Avoid stacking heavy objects on top of stored hoses, as this can cause deformation or permanent damage.

- Inspection: Regularly inspect the hose for signs of wear, such as cracks, abrasions, or leaks. Pay close attention to the connections and fittings, as these areas are more prone to damage. Replace damaged sections or fittings promptly to prevent further issues and ensure safety during use.

- Deployment and Retraction: Use proper techniques when deploying or retracting the hose to avoid unnecessary stress or kinking. Lay flat hose should be unrolled fully before use to prevent twists that may hinder flow. Similarly, retract the hose gently and store it properly to maintain its structural integrity and prolong its life.

Flat Hoses in the Future of Industrial Applications

The flat hose is evolving with advancements in materials and design. Innovations such as reinforced coatings, eco-friendly materials, and enhanced pressure capacities are making a lay flat hose more efficient and sustainable. These advancements allow flat hoses to perform better under harsh conditions, reducing the frequency of replacements and minimizing waste. For example, reinforced coatings provide greater resistance to wear and tear, extending the lifespan of hoses in heavy-duty operations like mining and dredging.

The shift toward eco-friendly materials is particularly significant as industries prioritize sustainability. By incorporating recyclable and biodegradable components, manufacturers are reducing the environmental footprint of flat hoses and a dredge hose. This aligns with the broader push toward green technologies in industrial sectors.

Emerging sectors, such as renewable energy and advanced manufacturing, are also finding new applications for flat hoses. For instance, in solar farm installations, flat hoses are used for efficient water transfer during cleaning and maintenance processes. Similarly, advanced manufacturing facilities utilize flat hoses and a dredge hose for cooling systems and chemical transfer, benefiting from their durability and adaptability.

The integration of dredge hose into cutting-edge industrial processes highlights their expanding relevance. These heavy-duty hoses are crucial for moving abrasive materials in sectors like renewable energy infrastructure development. Their ability to handle high-pressure flows and resist damage makes them an invaluable tool in modern industrial projects.

Conclusion

Flat hoses are indispensable in a variety of industrial applications, offering a unique combination of flexibility, durability, and efficiency. From dewatering construction sites to irrigating farmlands, their versatility and performance make them a preferred choice across sectors. By selecting the right flat hose and maintaining it properly, businesses can optimize operations and reduce costs.

If you’re considering flat hoses for your industrial needs, consult a trusted supplier to find the best options tailored to your requirements. Whether you need a reliable solution for firefighting, agriculture, or oil and gas, flat hoses, A lay flat hose, and dredge hose provide the performance and reliability you can count on.

0 Comments